Chemical Mixing Tanks

Chemical Mixing Tanks Specification

- Condition

- NEW

- Dimension (L*W*H)

- Custom as per requirement

- Application

- Chemical Mixing, Storage, Processing

- Processing

- Rotational Moulding / Fabrication

- Grade

- Industrial

- Tolerance

- 1% on dimensions

- Capacity

- 500 L to 10000 L (Standard variants available)

- Mixing Method

- Manual or Motorized Agitator (Optional)

- Installation

- Indoor / Outdoor

- Surface Finish

- Smooth (Easy to clean)

- Usage

- Suitable for Acids, Alkalis, and other Chemicals

- Material

- High Density Polyethylene (HDPE) / Polypropylene (PP)

- Fittings

- Flanged / Threaded / Customized

- Service Life

- >10 Years with Proper Maintenance

- Color

- White, Natural, or as required

- Leak Proof

- 100% Leak Proof Construction

- Corrosion Resistance

- Excellent

- Temperature Resistance

- -20°C to +80°C (depending on material)

- Top Cover

- Loose / Bolted / Hinged (Optional)

- Wall Thickness

- 5 mm to 20 mm (Depending on capacity)

- Shape

- Cylindrical / Rectangular / Customized

Chemical Mixing Tanks Trade Information

- Payment Terms

- Cheque

- Supply Ability

- Main Domestic Market

- All India

- Certifications

- INTERNAL TESTING CERTIFICATE, THIRD PARTY TESTING CERTIFICATE AS PER REQUIREMENT MATERIAL TESTING CERTIFICATE

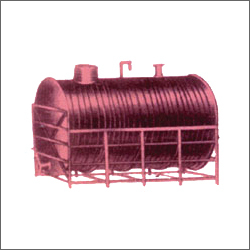

About Chemical Mixing Tanks

Manufactured using polypyrene and high density HDPE, our Chemical Mixing Tanks have complete static mixing design facility. Our advanced manufacturing division allows us to offer these tanks in varying diameters and capacities as per the clients requirements. The unique spiral winding process implemented by us enables us to make customized product as per clients specifications. Resistance to corrosion, rust, leakage and other attributes like strength, dimensional accuracy, light weight etc are highly appreciated in our tanks. These are used in various industry segments like chemical, petrochemical, textile, food, etc.

Durable Material and Customizable Design

Constructed from industrial-grade HDPE or PP, these chemical mixing tanks are engineered to withstand harsh environments and chemical exposures. With options for wall thickness and dimensions, each tank can be tailored to specific capacity requirements and installation spaces, ensuring seamless integration into various chemical handling processes.

Versatile Usage and Reliable Performance

These tanks support mixing, storage, and processing of a wide range of chemicals, including acids and alkalis. With temperature resistance from -20C to +80C (depending on material), excellent corrosion resistance, and 100% leak-proof construction, reliability and safety are ensured throughout prolonged industrial use.

Efficient Mixing and Easy Maintenance

Whether equipped for manual mixing or fitted with motorized agitators, chemical blending remains efficient. The tanks smooth surface finish facilitates easy cleaning, helping maintain hygiene standards and maximizing the service life, which can exceed ten years with routine maintenance.

FAQs of Chemical Mixing Tanks:

Q: How do I select the right material and wall thickness for my chemical mixing tank?

A: The choice between high-density polyethylene (HDPE) and polypropylene (PP) depends on the chemicals you intend to store and the required temperature resistance. Wall thickness, from 5 mm to 20 mm, should be selected based on the tanks capacity and the nature of the chemicals processed, balancing durability with cost-efficiency.Q: What customization options are available for shape, capacity, and fittings?

A: You can request tanks in cylindrical, rectangular, or specialized shapes, with capacities ranging from 500 L to 10,000 L. Fittings such as flanged, threaded, or customized types are available to suit your application and installation needs. Dimensions and wall thicknesses are tailored according to process specifications.Q: What is the recommended mixing method for these tanks?

A: Depending on batch requirements, you may opt for manual mixing or upgrade to motorized agitators for continuous or intensive mixing. Both options are compatible with these tanks, and your choice can be guided by the volume and nature of chemicals involved.Q: Where can these chemical mixing tanks be installed?

A: These tanks are suitable for both indoor and outdoor installations owing to their corrosion-resistant construction and temperature resilience. Installation location should also consider accessibility for maintenance and proximity to other process equipment.Q: What are the benefits of 100% leak-proof construction and smooth surface finish?

A: The leak-proof design ensures safe chemical storage and handling, minimizing the risk of spills and contamination. The smooth surface finish makes routine cleaning easy, promoting hygiene and helping preserve the tanks integrity over its extended service life.Q: How long do these chemical mixing tanks typically last with proper maintenance?

A: With appropriate usage and regular maintenance, such as cleaning and inspection, these industrial-grade tanks can offer reliable service for more than ten years, providing excellent long-term value.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Spiral Tanks Category

HDPE Rectangular Tank

Price 70000 INR / Piece

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Customized (As per requirement)

Tolerance : 2 mm

Condition : NEW

Grade : High Density Polyethylene (HDPE)

Spiral HDPE Tank

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : As per customer requirements (customizable)

Tolerance : 2% on dimensions and capacity

Condition : NEW

Grade : HighDensity Polyethylene (HDPE), Food Grade

Horizontal Storage Tanks

Price 50000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Dimension (L*W*H) : Customized (As per requirement)

Tolerance : 1% of capacity

Condition : NEW

Grade : SS304 / SS316 / Mild Steel

HDPE Liquid Storage Tanks

Minimum Order Quantity : 100 Units

Dimension (L*W*H) : As per requirement / Customizable

Tolerance : 2 mm

Condition : NEW

Grade : Industrial grade

We are mainly dealing in Hyderabad, Andhra Pradesh, Telangana and Maharashtra.

|

SPIRALL PLASTICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry