à¤à¤à¤¡à¥à¤ªà¥à¤ पिà¤à¤²à¤¿à¤à¤ à¤à¥à¤à¤

à¤à¤à¤¡à¥à¤ªà¥à¤ पिà¤à¤²à¤¿à¤à¤ à¤à¥à¤à¤ Specification

- एप्लीकेशन

- Pickling process, chemical storage, electroplating industry

- प्रोसेसिंग

- Welded and fabricated

- शर्त

- आयाम (एल* डब्ल्यू* एच)

- As per client requirement

- सहनशीलता

- ±2 mm

- ग्रेड

- HDPE (High Density Polyethylene)

- क्षमता

- Up to 60,000 liters (customizable)

- Shape Options

- Rectangular, Cylindrical, or as per design

- Leak Proof

- Yes, tested for leakage

- Color

- Black, White, or as specified

- Compliance

- Manufactured as per international standards (IS 8038)

- UV Resistance

- High

- Temperature Resistance

- Up to 80°C

- Material Thickness

- 8 mm – 40 mm

- Surface Finish

- Smooth, semi-glossy

- Installation

- On-site as per requirement

- Accessories

- Lids, drain valve, overflow, inlet & outlet nozzles

- Reinforcement

- External MS/FRP support as required

- Corrosion Resistance

- Excellent, suitable for acids and chemicals

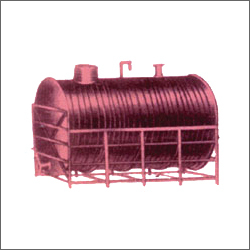

About à¤à¤à¤¡à¥à¤ªà¥à¤ पिà¤à¤²à¤¿à¤à¤ à¤à¥à¤à¤

Used in galvanizing plants and pickling plant, HDPE Pickling Tanks are primarily designed and developed to carry out pickling processes of stainless steel or mild steel coils in addition to pipes and bars. These tanks find extensive applications in pickling, powder coating, chrome plating, electroplating, re rolling etc. Manufactured using high density HDPE, these tanks corrosion and leakage resistant as well as durable to withstand high temperature. These are high performance tanks which require less maintenance and are available in various capacities. Besides, these are provided in different shapes and sizes to suit specific applications.

उत्पाद विवरण:

|

Storage Capacity |

1000L |

|

Color |

Black |

Specification:

- Capacity: 30.0 Gallons

- Item Weight: 8 Ounces

- Shape: Rectangular

Exceptional Durability and Customization

Our HDPE Pickling Tanks are designed for industrial reliability, featuring robust material thickness, superior UV resistance, and excellent performance against corrosive substances. Both dimensions and shapes are fully customizable, making them suitable for various applications, from chemical storage to electroplating processes. Each tank is fabricated with precision, ensuring a smooth, semi-glossy surface finish and meeting the strictest international standards for quality and safety.

Advanced Engineering for Industrial Needs

These tanks are manufactured using state-of-the-art processing methods, including welded and fabricated construction. External mild steel (MS) or fiberglass reinforced plastic (FRP) reinforcements can be added as per site requirements. Leak testing and thorough quality checks are integral, guaranteeing peace of mind and safe operation in demanding environments. A range of accessories, from lids to inlets and drainage systems, enhance usability and operational efficiency.

FAQs of HDPE Pickling Tank:

Q: How is the HDPE Pickling Tank installed on-site?

A: The HDPE Pickling Tank is installed directly at your facility by our expert team, following your sites specifications. External reinforcement using MS or FRP supports is provided as needed to ensure stability and safety. All installations adhere to international standards for reliability.Q: What types of chemicals or acids can these tanks safely store?

A: These tanks are specifically engineered for high resistance to a wide range of acids and chemicals, thanks to their corrosion-resistant HDPE construction. This makes them suitable for pickling processes, chemical storage, and use in the electroplating industry.Q: When should I opt for external reinforcement such as MS or FRP support?

A: External reinforcement is recommended for large-capacity tanks, tanks intended for heavy-duty industrial use, or when installed in demanding conditions. Our team will assess your application and advise on the optimal reinforcement solution to ensure durability and safety.Q: Where are HDPE Pickling Tanks typically used?

A: They are widely used across various industries in India, including chemical manufacturing, electroplating, and metal pickling plants. The tanks are also suitable for any facility needing reliable, leak-proof, and corrosion-resistant storage and processing solutions.Q: What is the manufacturing process for these tanks?

A: Each tank is fabricated from high-quality HDPE sheets using advanced welding techniques. The process involves careful cutting, welding, and forming to meet client-specific dimensions, followed by rigorous leak and quality testing pre-dispatch.Q: How does the tanks design benefit my operations?

A: Customizable shapes and capacities, superior chemical resistance, high UV tolerance, and robust construction ensure long-lasting, low-maintenance performance. Accessories like lids, drain valves, and nozzles enhance operational convenience and spill prevention.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in HDPE Spiral Tanks Category

सर्पिल एचडीपीई टैंक

एप्लीकेशन : Chemical storage, water storage, pharmaceuticals, food processing, waste management

शर्त : NEW

ग्रेड : HighDensity Polyethylene (HDPE), Food Grade

न्यूनतम आदेश मात्रा : 1

आयाम (एल* डब्ल्यू* एच) : As per customer requirements (customizable)

सहनशीलता : ±2% on dimensions and capacity

क्षैतिज भंडारण टैंक

एप्लीकेशन : Industrial liquid storage

शर्त : NEW

ग्रेड : SS304 / SS316 / Mild Steel

न्यूनतम आदेश मात्रा : 1

आयाम (एल* डब्ल्यू* एच) : Customized (As per requirement)

सहनशीलता : ±1% of capacity

एचडीपीई केमिकल स्टोरेज टैंक

एप्लीकेशन : Chemical storage, Water treatment, Industrial liquids

शर्त : NEW

ग्रेड : Virgin HDPE (High Density Polyethylene)

न्यूनतम आदेश मात्रा : 1

आयाम (एल* डब्ल्यू* एच) : As per client requirement (customizable)

सहनशीलता : ±2% on dimensions and capacity

फार्मास्युटिकल स्टोरेज टैंक

एप्लीकेशन : Pharmaceuticals, Chemical, Food & Beverage Storage

शर्त : NEW

ग्रेड : Pharmaceutical Grade SS316L / SS304

न्यूनतम आदेश मात्रा : 100

आयाम (एल* डब्ल्यू* एच) : As per Client Requirement

सहनशीलता : ±0.5 mm

हम मुख्य रूप से हैदराबाद, आंध्र प्रदेश, तेलंगाना और महाराष्ट्र में काम कर रहे हैं।

|

SPIRALL PLASTICS

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें