फारà¥à¤®à¤¾à¤¸à¥à¤¯à¥à¤à¤¿à¤à¤² सà¥à¤à¥à¤°à¥à¤ à¤à¥à¤à¤

फारà¥à¤®à¤¾à¤¸à¥à¤¯à¥à¤à¤¿à¤à¤² सà¥à¤à¥à¤°à¥à¤ à¤à¥à¤à¤ Specification

- क्षमता

- 500 Litres to 50,000 Litres

- आयाम (एल* डब्ल्यू* एच)

- As per Client Requirement

- एप्लीकेशन

- Pharmaceuticals, Chemical, Food & Beverage Storage

- प्रोसेसिंग

- Welding, Polishing, Assembling

- शर्त

- सहनशीलता

- ±0.5 mm

- ग्रेड

- Pharmaceutical Grade SS316L / SS304

फारà¥à¤®à¤¾à¤¸à¥à¤¯à¥à¤à¤¿à¤à¤² सà¥à¤à¥à¤°à¥à¤ à¤à¥à¤à¤ Trade Information

- Minimum Order Quantity

- 100 Units

- भुगतान की शर्तें

- चेक

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

- प्रमाणपत्र

- INTERNAL TESTING CERTIFICATE, THIRD PARTY TESTING CERTIFICATE AS PER REQUIREMENT MATERIAL TESTING CERTIFICATE

About फारà¥à¤®à¤¾à¤¸à¥à¤¯à¥à¤à¤¿à¤à¤² सà¥à¤à¥à¤°à¥à¤ à¤à¥à¤à¤

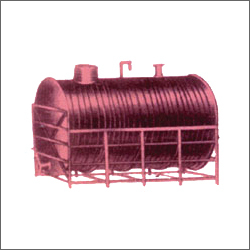

Pharmaceutical Storage Tanks are durable and convenient solution for the safe storage of dry chemical powders, pharmaceuticals etc in chemical pharmaceutical, food processing industries. These are made using high density polyethylene which provides resistance to corrosion and make them fit for holding the most demanding applications. These tanks are high versatile featuring long life even with repeated applications and corrosion resistant structure. Manufactured as per the industry standards and safety regulations, these tanks are provided in different capacities to suit clients specific applications. Apart from this, these tanks can also be customized and are available at industry leading prices.

उत्पाद विवरण:

| Storage Capacity | 1500L, 2000L |

| Color | Black, Grey, Natural |

- Lightweight

- Durable

- Leak proof

- Low maintenance

Advanced Material and Surface Options

Constructed from pharmaceutical-grade Stainless Steel 316L or 304, these tanks offer both exceptional durability and resistance to corrosion. Internal and external surfaces can be finished to a high-sheen mirror polish or a specialized matt finish, promoting increased cleanliness and reduced contamination risks in pharmaceutical applications.

Versatile Design Customization

Each storage tank can be tailored to your process needs, offering insulation, jacketed options for both chilled and heated storage, and flexible inlet/outlet fittings including tri-clamp and flanged connections. Mounting options (legs, skirt, or saddle) allow installation in diverse facility layouts.

Regulatory Compliance and Quality Assurance

Our tanks are meticulously fabricated in accordance with cGMP, FDA, and ASME guidelines. They undergo hydrostatic and radiographic testing to assure structural integrity and safety. Precision argon arc (TIG) welds and mirror-polished seams further guarantee compliance and ease of cleaning.

FAQs of Pharmaceutical Storage Tanks:

Q: How are your pharmaceutical storage tanks customized for different applications?

A: We offer full customization in material choice (SS316L or SS304), surface finish, capacity (500 to 50,000 litres), insulation, and jacketed construction for temperature-controlled storage. Mounting, inlets, outlets, manholes, agitator options, and accessory provisions are tailored to your operational and regulatory requirements.Q: What process is followed to ensure the quality and compliance of these storage tanks?

A: All tanks undergo rigorous hydrostatic and radiographic testing, ensuring leak-proof performance. We utilize argon arc welding (TIG) for seamless joins, followed by mirror polishing for hygienic surfaces, in compliance with cGMP, FDA, and ASME standards.Q: When should I consider using a jacketed storage tank?

A: A jacketed storage tank is ideal when you require chilled or heated storage to maintain precise temperature control for pharmaceuticals, chemicals, or sensitive products. The jacket enables circulation of cooling or heating media as needed.Q: Where can your tanks be installed, and what mounting options are available?

A: Our storage tanks are suitable for installation across pharmaceutical, chemical, and food & beverage facilities, with mounting styles including legs, skirt, or saddle. This flexibility ensures compatibility with diverse plant layouts and operational requirements.Q: What are the benefits of mirror-polished surfaces for storage tanks?

A: Mirror polishing enhances the tanks cleanability, helps prevent microbial buildup, and minimizes contamination risks. These features are vital in pharmaceutical environments where hygiene and ease of sterilization are paramount.Q: How do the available accessories improve tank usage and monitoring?

A: Accessories such as level indicators, vent filters, temperature gauges, and CIP/SIP provisions facilitate process monitoring, automation, and efficient sanitation, optimizing operational safety and product integrity.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in HDPE Tanks Category

एचडीपीई आयताकार टैंक

शर्त : NEW

एप्लीकेशन : Chemical Storage, Water Treatment, Pickling, Plating, Effluent Storage

ग्रेड : High Density Polyethylene (HDPE)

प्रोसेसिंग : Moulded / Fabricated

मूल्य या मूल्य सीमा : आईएनआर

आयाम (एल* डब्ल्यू* एच) : Customized (As per requirement)

एचडीपीई थर्माप्लास्टिक टैंक

शर्त : NEW

एप्लीकेशन : Chemical Storage, Water Storage, Industrial Storage

ग्रेड : Virgin HDPE

प्रोसेसिंग : Rotational Moulding

मूल्य या मूल्य सीमा : आईएनआर

आयाम (एल* डब्ल्यू* एच) : 1200 mm x 900 mm x 1200 mm

क्षैतिज भंडारण टैंक

शर्त : NEW

एप्लीकेशन : Industrial liquid storage

ग्रेड : SS304 / SS316 / Mild Steel

प्रोसेसिंग : Welded Construction

मूल्य या मूल्य सीमा : आईएनआर

आयाम (एल* डब्ल्यू* एच) : Customized (As per requirement)

आयताकार पिकलिंग टैंक

शर्त : NEW

एप्लीकेशन : Pickling, Galvanizing, Chemical Storage

ग्रेड : Virgin Polypropylene (PP)

प्रोसेसिंग : Extrusion and Welding

मूल्य या मूल्य सीमा : आईएनआर

आयाम (एल* डब्ल्यू* एच) : Customized as per requirement

हम मुख्य रूप से हैदराबाद, आंध्र प्रदेश, तेलंगाना और महाराष्ट्र में काम कर रहे हैं।

|

SPIRALL PLASTICS

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें