à¤à¤à¤¡à¥à¤ªà¥à¤ सरà¥à¤ªà¤¿à¤² सà¥à¤à¥à¤°à¤¬à¤°à¥à¤¸

à¤à¤à¤¡à¥à¤ªà¥à¤ सरà¥à¤ªà¤¿à¤² सà¥à¤à¥à¤°à¤¬à¤°à¥à¤¸ Specification

- सतह का उपचार

- Smooth / Polished

- पावर सोर्स

- Electric / Process Driven

- टेक्नोलॉजी

- Spiral Winding

- सटीकता

- High removal efficiency

- ऑपरेटिंग प्रेशर

- Ambient / Atmospheric

- सहायक उपकरण का प्रकार

- Nozzles, Demister Pads, Drain Valves

- मशीन का प्रकार

- Wet Scrubber

- टाइप करें

- Gas Scrubber

- मटेरियल

- HDPE (High Density Polyethylene)

- फंक्शन

- Removal of fumes, gases, and particulates

- एप्लीकेशन

- Industrial air pollution control, chemical processing plants

- वोल्टेज

- 230 V / 415 V (if equipped with pumps or auxiliary systems)

à¤à¤à¤¡à¥à¤ªà¥à¤ सरà¥à¤ªà¤¿à¤² सà¥à¤à¥à¤°à¤¬à¤°à¥à¤¸ Trade Information

- भुगतान की शर्तें

- चेक

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- दिन

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

- प्रमाणपत्र

- INTERNAL TESTING CERTIFICATE, THIRD PARTY TESTING CERTIFICATE AS PER REQUIREMENT MATERIAL TESTING CERTIFICATE

About à¤à¤à¤¡à¥à¤ªà¥à¤ सरà¥à¤ªà¤¿à¤² सà¥à¤à¥à¤°à¤¬à¤°à¥à¤¸

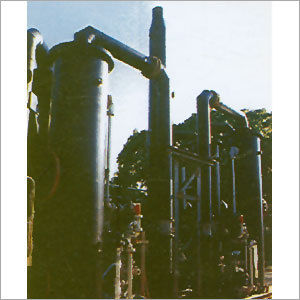

We have gained recognition by offering premium quality fume scrubbers which are essential in the protection of environment. Commonly known as HDPE Spiral Scrubbers, these devices find extensive applications in different domains including corrosive or hazardous chemicals. Installed at various locations, these highly efficient scrubbers are useful in releasing non toxic vapors in the environment generated during industrial processes. We procure quality plastic from authorized vendors for manufacturing these and its accessories. These are easy to use and install and have long functional life. Besides, these are tested on various quality parameters prior to installation and are available at competitive prices.

What Makes HDPE Spiral Scrubbers Unique?

These scrubbers stand out due to their spiral winding construction from high-density polyethylene, offering superior corrosion resistance and structural strength. The smooth, polished surface minimizes fouling and facilitates easy cleaning, making them perfect for aggressive chemical environments and high-efficiency air pollution control.

Applications in Industrial Air Pollution Control

Primarily used in industrial and chemical processing plants, HDPE Spiral Scrubbers excel at removing hazardous gases, acid fumes, and particulates from exhaust air. Their robust design and precise engineering make them suitable for continuous operation under challenging conditions, ensuring compliance with environmental regulations.

FAQs of HDPE Spiral Scrubbers:

Q: How do HDPE Spiral Scrubbers function to remove contaminants from industrial exhausts?

A: HDPE Spiral Scrubbers operate as wet scrubbers, using water or chemical solutions sprayed through nozzles to interact with contaminated gas streams. This process absorbs and neutralizes fumes, gases, and particulates, which are then collected for safe disposal or treatment.Q: What are the benefits of choosing spiral wound HDPE material for gas scrubbers?

A: Spiral wound HDPE provides exceptional chemical resistance, durability, and lightweight construction. Its smooth or polished finish reduces buildup and simplifies cleaning, leading to longer service life and reduced maintenance in harsh industrial environments.Q: When should industries opt for HDPE Spiral Scrubbers over other air pollution control equipment?

A: HDPE Spiral Scrubbers are best suited when dealing with corrosive or aggressive gases and particulates, especially in applications where traditional metal scrubbers may corrode or require frequent maintenance. Theyre ideal when high removal efficiencies and low operational costs are essential.Q: Where are HDPE Spiral Scrubbers typically installed within industrial plants?

A: These scrubbers are commonly positioned at exhaust points of processes generating harmful gases or particulates, such as reactors, storage tanks, or emission stacks, ensuring contaminants are captured before release into the environment.Q: What is the installation process for an HDPE Spiral Scrubber system?

A: The system is typically installed by connecting the scrubber to the process exhaust duct, water/chemical supply lines, and drain outlets. Accessories like nozzles, demister pads, and drain valves are fitted as required. Electrical connections are made if pumps or auxiliary systems are utilized.Q: How do you maintain an HDPE Spiral Scrubber for long-term efficiency?

A: Regular inspection of nozzles, demister pads, and drains is recommended. Periodic cleaning of internal surfaces and prompt replacement of worn accessories help sustain optimal performance and extended equipment life.Q: What makes HDPE Spiral Scrubbers an efficient choice for gas removal in chemical plants?

A: Their high removal efficiency is achieved through optimized wet scrubbing mechanisms and corrosion-resistant construction, offering reliable protection against chemical fumes, coupled with ease of maintenance and adaptability to various industrial processes.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in HDPE Scrubbers Category

एचडीपीई औद्योगिक स्क्रबर

मटेरियल : HDPE (HighDensity Polyethylene)

कंट्रोल सिस्टम : PLC Based/Manual

वोल्टेज : 380V / 415V

सटीकता : High Efficiency (>95% removal efficiency)

टेक्नोलॉजी : Wet Scrubbing

पीपी औद्योगिक स्क्रबर

मटेरियल : Polypropylene (PP)

कंट्रोल सिस्टम : PLC Based Control Panel

वोल्टेज : 220415 V

सटीकता : Efficient gas scrubbing upto 99%

टेक्नोलॉजी : Wet Scrubbing

पीपी स्क्रबर

मटेरियल : Polypropylene (PP)

न्यूनतम आदेश मात्रा : 1

कंट्रोल सिस्टम : Mechanical Control

वोल्टेज : 220V/380V

सटीकता : High

टेक्नोलॉजी : Wet Scrubbing Technology

हम मुख्य रूप से हैदराबाद, आंध्र प्रदेश, तेलंगाना और महाराष्ट्र में काम कर रहे हैं।

|

SPIRALL PLASTICS

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें